Making my first pipe

I would like to start this blog with presenting how I made my first pipe. What You can see on these first two pictures bellow is a briar piece of wood like I received it – it was ordered as a kit, prebored and the stem was fitted and bent.

First, I was thinking about the design. The block was huge, so a really big pipe could be made out of it. Also, I wanted to leave the bark on the top. So, the pipe would be also very tall.

After I managed to decide on a shape the next step of the process could start.

Briar that could not be used in this project was removed using a saw blade.

After that I used sandpaper 80 and 120 to roughly shape the future pipe…

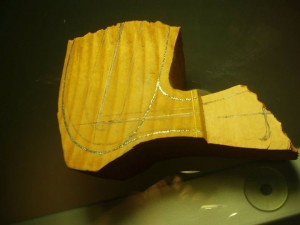

When sanding the piece down, I was using a paper reference to help me sand the pipe according to the shape.

When the predetermined shape was met and I was satisfied with it, sanding with finer sandpapers started… Sandpaper 220 and 400 were used. After sandpaper 400 I stained the pipe using water based black stain and sanded again with used 400 sandpaper. The result can be seen on the following pictures.

After that I proceed with sanding and went to a finer gradation of sandpaper. 400, 600 and 800 sandpapers were used… After each gradation I stained the pipe in black heating the wood before staining to allow the stain to penetrate the wood more. The result can be seen below….

After this I thought that it would be nice to stain the pipe with a palisander colored stain.

Bellow is the result.

After the sanding was done, polishing on a wheel using brown tripoli was made.. Three layers of carnauba wax were next (with melting the first layer using a heat gun to allow carnauba to penetrate the wood more) and the result was a finished pipe… 🙂